Sand Casting – India and Mexico

State-of-the-art facilities.

Diverse product range.

Sand – India and Mexico

- Manufacturing Capacity

- Manufacturing Range

- Design and Engineering

- Melting

- Shell Molding

- No Bake Molding

- Heat Treatment

- High Alloy

- Finishing Cells

Manufacturing Capacity

Matrix can offer a wide range of castings

- Sand/Shell

- As cast or machined

- Single piece weight

- Sand Foundry – 5 Kgs to 7500 Kgs

- Metallurgies – Full range of Carbon / Stainless steel, Cr-Ni-Mo alloy steel, Nickel based Alloys &

Super high alloys - Pressure holding high integrity castings with complex geometries

Well supported by robust business processes

- Foundry engineering services – fab to cast design & Re-engineering of design

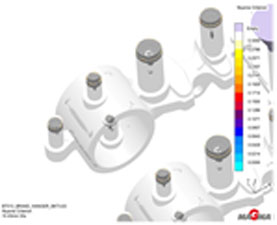

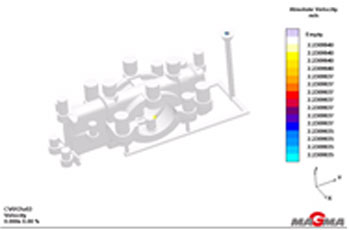

- Simulation by latest version of Magma 5.4 – A standard practice for NPD

- Ability to handle small and large batch sizes

- Onsite upgrade & NDE capabilities

- RT, X ray, MPI, UT, DP, Hardness & Visual testing to meet customized solutions and stringent specifications

- Dedicated customer support team

- Integrated IT systems

Manufacturing Range

Job Size & Weight Limitations:

Sand Castings

| Linear | upto 2000 mm |

| Diameter | upto 2000 mm |

| Maximum Piece Weight | 7.5 Tons |

Manufacturing Processes

| No-bake Processes : Flask/ Flaskless/ Shell |

Design and Engineering

In-house magma software for pouring simulation pro engineering for methoding leveraging

engineering capability to

enhance productivity elimination needless process & reduction re-work.

Melting

Melting Furnaces:

- Arc/Induction Furnaces in Mexico and Induction Furnaces in India – various crucible

sizes thereby allowing flexibility

in batch quantities - Metal Refining Capability (AOD)

Shell Molding

- Twin molding machines 650 x 750 mm

No Bake Molding

- Fully automated flask less molding lines with Roll Over, flood coating, Drying Tunnel & Auto Closer

- Manual Lines for large castings

Continuous Mixer

Roll Over

Flood Coating

Auto Closer

Heat Treatment

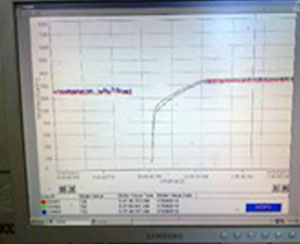

- Battery of Heat Treatment Furnaces controlled by state-of-the-art SCADA

- Capacities from 3 Tons to 10 Tons per Charge

- Assure precise temperature control

- Calibrated to the Following Standards

- API 6D

- STM A 991

- AMS 2750 E

- In-house Water Quenching with Impeller Agitation System

Castings in HT furnace

Time Temp. Measurement

Programmable rate of heating

Process monitoring

Quenching

High Alloy

- Special Blast for Stainless Steel and High alloys

- Improved quality and eliminates rust spots caused by iron contamination on

stainless castings

- Improved quality and eliminates rust spots caused by iron contamination on

Finishing Cells

- Upgrade and Grinding cells

Get in touch

Business Headquarters

MATRIX METALS

Stafford Grove Industrial Park Bldg.

B 10643 West Airport Blvd.,

SUITE 100

Stafford, Texas – 77477

USA Tel.: +1 281 633 4200

Mexico Tel.: +52 427 271 8600

India Tel.: +91 4339 222 210

If you would like us to call you, please share your contact number and country. We will get in touch with you soon.